SPIRAL WOUND SPACER MEMBRANES

SPARO is a spiral wound membrane with a unique engineered spacer technology designed for overcoming the fouling & scaling problems typically found in the spiral wound membranes. Most water treatment applications, especially wastewater recycling, typical spiral wound membranes are not able to cop up with COD, BOD and Suspended matter. Vast pre-treatment is required in most cases.

SPARO TECHNOLOGY

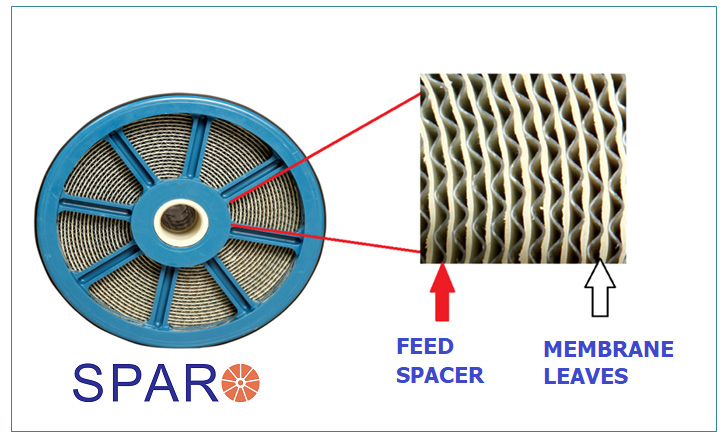

We have perfected the chemistry of membranes and engineering of the spacer. Feed spacer determines the flow pattern, fluid dynamics and turbulence distribution in the membrane module. Our spacer technology with higher thickness and proprietary geometrical design will enhance the performance of the spiral membrane design with superior fluid dynamics.

The membranes are made of advanced membrane chemistry. Membranes are manufactured with a symmetrical proposition, pure polyamide link between two buildings compound which gives unique stability and chemical durability. Also, it contains exclusive polyamide chemistry in the polymer web which strengthens the structure. The physical property of the membrane’s surface is permanently modified to provide a hydrophilic character in the surface along with near-neutral charges. The membranes are with following features…

Hydrophilic membranes

Near neutrally charged

Low affinity to the organic matter

Minimize the adsorption of organic foulants

Less flux degradation

SPARO membranes are widely used in effluent and wastewater treatment applications where suspended, and the turbid matter is moderately present. In many cases, costly pre-treatment such as ultrafiltration can be avoided as the membranes can perform with a higher SDI limit and are tolerant to turbidity to a greater extent.

SPARO membranes can be accommodated in a typical spiral wound membrane plant due to their dimensions advantages. Often no modification or little modifications are required. Hence, it is an ideal replacement for the existing system.